The Role of Membrane Switches in Enhancing Product Durability and Performance

The Role of Membrane Switches in Enhancing Product Durability and Performance

Blog Article

Membrane Layer Switch Technology: The Secret to Reliable and Cost-efficient User Interfaces

Membrane button technology has emerged as a crucial element in the design of user interfaces, giving both integrity and cost-effectiveness throughout a varied range of applications. As we check out the diverse benefits of membrane layer buttons, their possibility for technology raises concerns regarding future applications and evolving fads.

Recognizing Membrane Layer Switch Innovation

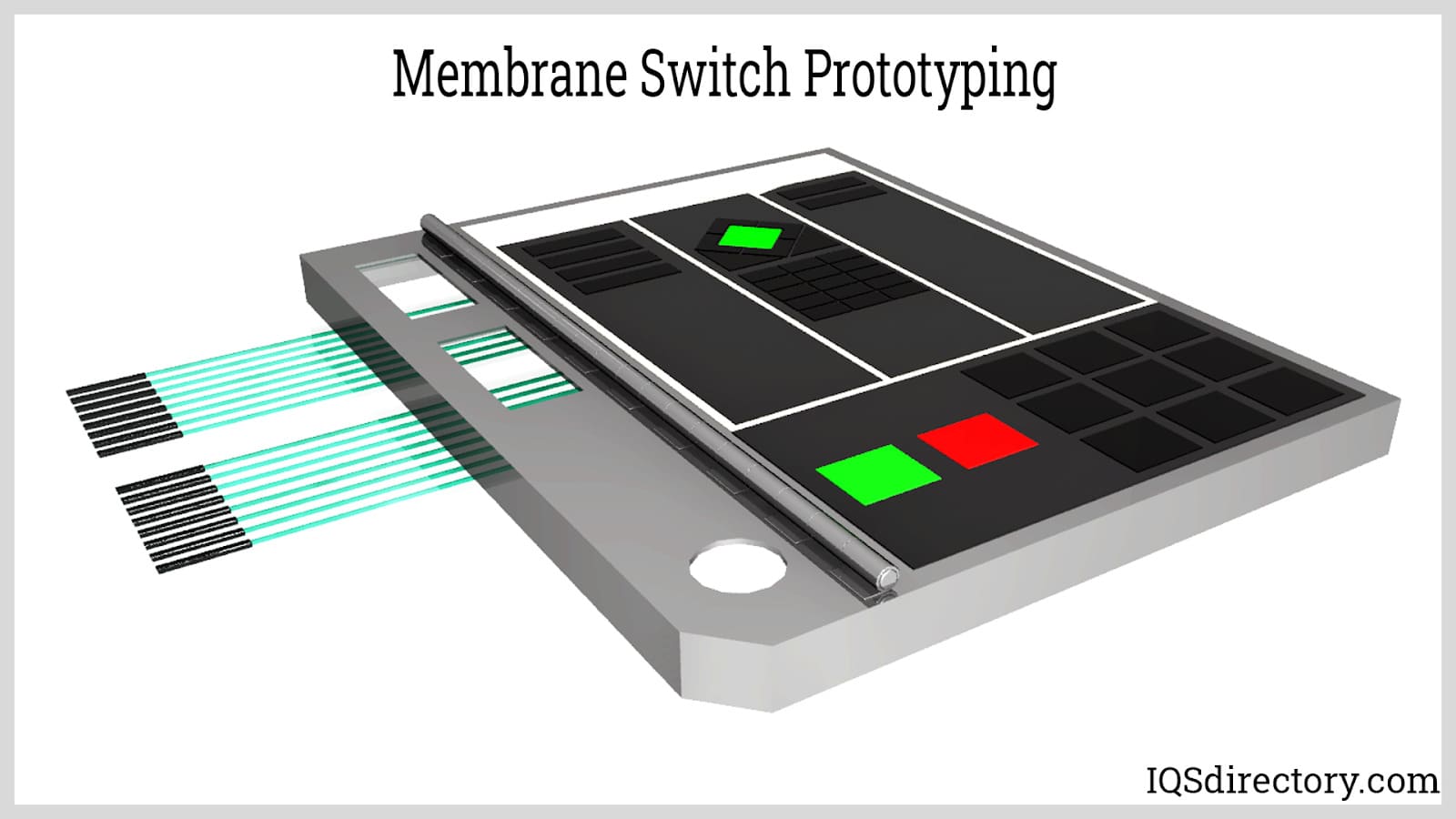

Membrane switch modern technology is a commonly used user interface remedy in various electronic devices, supplying a seamless mix of functionality and layout. This technology incorporates multiple layers of products, generally being composed of a visuals overlay, spacer layer, and a circuit layer. The visuals overlay presents the user interface elements, while the spacer layer separates the circuit layer from the overlay up until a customer triggers a button.

When pressure is put on the overlay, the circuit layer completes the electrical circuit, sending a signal to the device. This mechanism allows for various setups, including tactile responses and backlighting alternatives, improving customer communication. Membrane layer buttons are usually produced making use of durable products such as polyester or polycarbonate, ensuring long life and resistance to ecological elements like moisture and dust.

The versatility of membrane switches allows their application in varied sectors, consisting of medical devices, consumer electronics, and industrial controls. Their portable design enables combination right into space-constrained atmospheres, supplying an efficient interface without compromising visual allure. Recognizing the details of membrane button technology is important for suppliers and developers seeking to produce trusted and reliable human-machine interfaces.

Key Benefits of Membrane Buttons

While various user interface services exist, membrane layer switches over deal distinct benefits that make them a recommended choice in numerous applications. One of the main advantages is their resilience; membrane layer switches are made to hold up against extreme environmental problems, consisting of wetness, dust, and temperature level changes, making certain long-lasting performance. This resilience substantially reduces the need for frequent substitutes, thus reducing overall maintenance prices.

Moreover, membrane layer buttons are light-weight and portable, making them suitable for applications where space is limited. Their inconspicuous layout adds to a streamlined appearance without endangering functionality.

Cost-effectiveness is also a remarkable advantage, as the production procedure for membrane switches over has a tendency to be cheaper contrasted to typical mechanical switches. This affordability, integrated with their dependability and ease of setup, positions membrane changes as a practical solution for a variety of industries looking for efficient and reliable customer interfaces.

Applications Across Numerous Industries

Just how do membrane buttons adapt to the diverse needs of various industries? Membrane layer switch modern technology is increasingly recognized for its convenience, making it ideal for a vast variety of applications throughout several industries.

In customer electronic devices, membrane layer buttons offer a portable remedy for remotes and home appliances, enhancing customer experience through instinctive design. Additionally, the commercial industry leverages membrane buttons for machinery control board, gaining from their resistance to harsh settings, click this such as wetness and dust.

Armed forces and aerospace applications additionally use membrane layer buttons for their integrity and capacity to hold up against severe problems, guaranteeing functional performance in crucial circumstances. Additionally, the food and drink industry embraces these switches for automated systems, where sanitation and simplicity of procedure are vital. Eventually, membrane layer buttons are tailored to satisfy the one-of-a-kind needs of each industry, proving their vital role in modern-day innovation interfaces

Style and Modification Options

In the world of membrane layer button innovation, style and modification alternatives play a pivotal function in enhancing performance and user communication. These switches can be customized Extra resources to fulfill certain functional needs and visual preferences, making them flexible parts in various applications.

Among the main modification options is the layout of the button itself, which can be created to accommodate one-of-a-kind customer interfaces and ergonomic factors to consider. By adjusting the form, size, and plan of buttons, producers can develop instinctive layouts that help with ease of use. Furthermore, the consolidation of various shades and visuals overlays permits branding and boosted presence, ensuring that individuals can rapidly determine functions.

In addition, membrane buttons can be engineered with different responsive feedback mechanisms, such as increased buttons or distinct clicks, to boost the customer experience. Various products can likewise be chosen for resilience and environmental resistance, resolving factors such as wetness, temperature variations, and chemical exposure.

Ultimately, the extensive style and modification options readily available in membrane layer button technology encourage businesses to produce tailored solutions that not only satisfy useful requirements however likewise align with their branding and operational requirements.

Future Patterns in Membrane Switches

As membrane layer button innovation proceeds to advance, future fads are significantly concentrated on improving customer experience and integrating sophisticated performances. One considerable pattern is the assimilation of hop over to these guys touch-sensitive and capacitive modern technologies right into traditional membrane layer switches. This advancement enables for even more instinctive interface, giving responsive comments while keeping a sleek style.

An additional emerging trend is the use of ecologically friendly products, driven by the growing need for sustainable production techniques. Manufacturers are looking for to minimize their carbon impact by making use of recyclable substrates and low-impact inks, aligning with worldwide sustainability objectives.

Furthermore, the rise of the Internet of Points (IoT) is prompting the unification of clever functions right into membrane layer buttons. Enhanced connection choices will certainly enable tools to interact with each various other, enabling smooth assimilation into broader systems.

In addition, innovations in printing modern technologies, such as digital printing, are permitting better style flexibility and modification. This enables makers to generate intricate layouts and dynamic colors cost-effectively.

Final Thought

To conclude, membrane layer switch modern technology represents a crucial development in interface design, offering significant benefits in longevity, customization, and cost-effectiveness. Its prevalent applicability across diverse sectors highlights its value in contemporary technology. As innovations continue to emerge, especially in touch-sensitive interfaces and sustainable products, the capacity for membrane switches to boost individual experience and performance continues to be encouraging. Proceeded expedition of this modern technology will likely yield better enhancements and broaden its range in future applications.

Report this page